The functioning of the e p r o t e c melt-X pumps

Gear pumps are commonly used for the precise transfer and metering of polymers, fuel and chemical additives. In extrusion application gear pumps (melt pumps) stabilize the process by generating a constant pressure, therefore ensuring a constant flow of material and relieving the extruder from the pressure build-up.

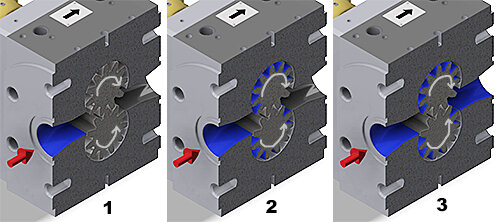

1. The volumetric pumping device has two externally toothed gearwheels which mate each

other when they rotate. A small pressure in the pump inlet is sufficient to fill the tooth

chambers.

2. On the discharge side, the mating of the gear teeth in each other discharges the melt out of

the tooth chamber.

3. Two slide bearings per gear shaft absorb the forces. They are lubricated by the

polymer and are maintenance free.

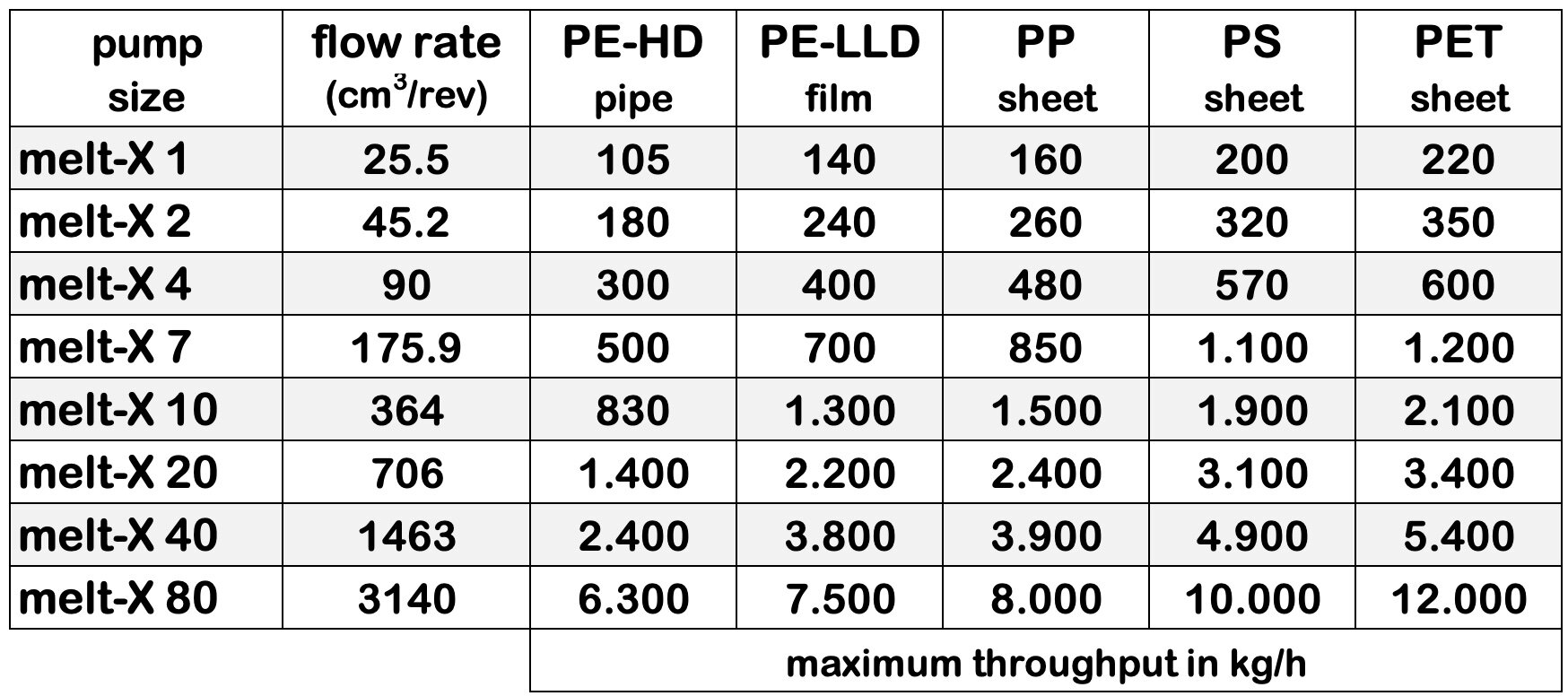

Throughput and limits of melt-X gear pumps:

Temperature max.: 350°C

Diff. pressure: 250 bar (melt-X H 500 bar)

Viscosity: 5 - 20.000 Pas