All melt pumps are cubical!

But the most important differentiation is found in the detail!

eprotec is the only melt pump manufacturer with full nitriding depth on the teeth.

Our melt pumps always carry two pressure sensor threads in the pump housing in the flat part of the product channel and two different threads for thermocouples on both sides.

Perfect features

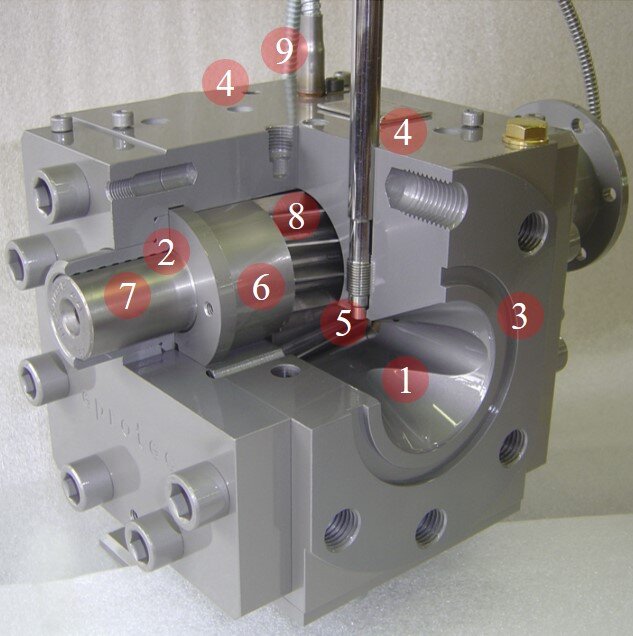

1) Flow-optimised product channel

2) Maximum reduction of stagnation volume

3) Smaller product channel for fast product - color change

4) Integrated threads for pressure sensors

5) Accurate place for pressure sensor in flat area

6) Bearings (bushings) hardened, special tool steel

7) Gear shafts special hardening process

8) Long service life teeth with max. nitriding depth

9) Heating cartridges: zone-adapted heating power

(40/20/40%)

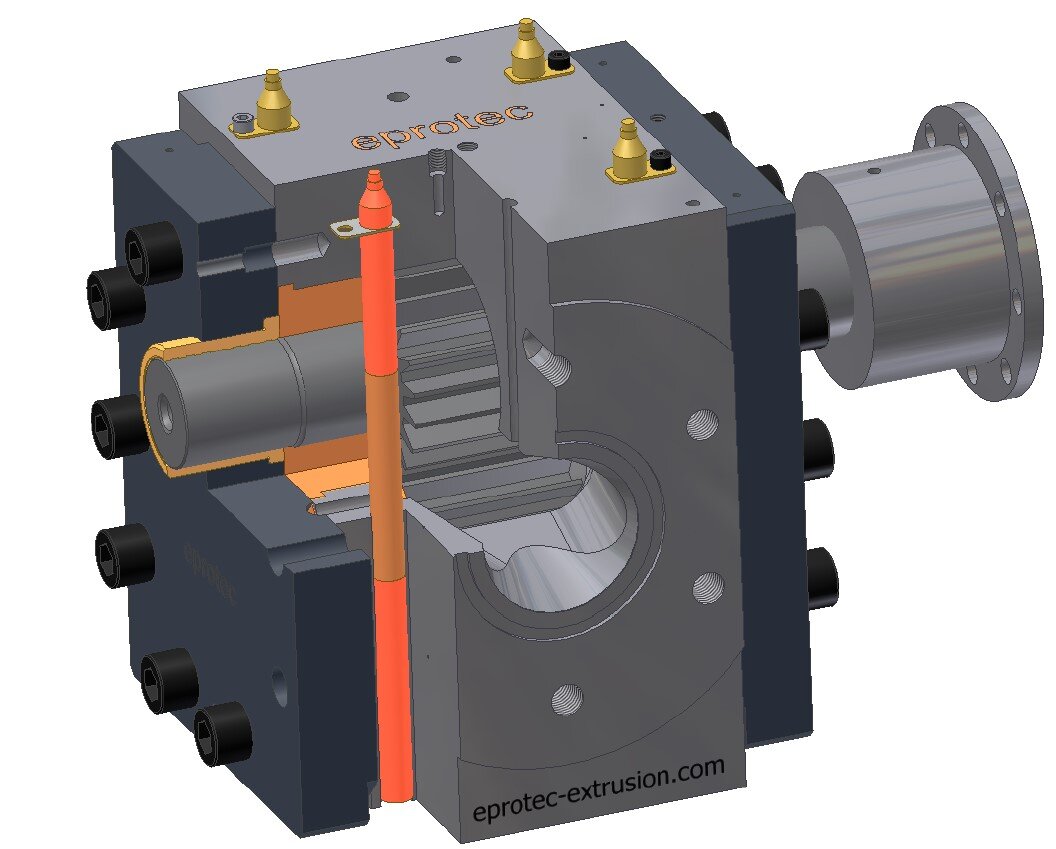

More features

- Components with index

- No mix-up of components during assembly

- From outside you see whether the melt pump was

correctly assembled

- Heating cartridges with 3-zone output

- Assembly of the heating cartridges from top and below

- Temperature sensor connections M12 and M14 on top

and below