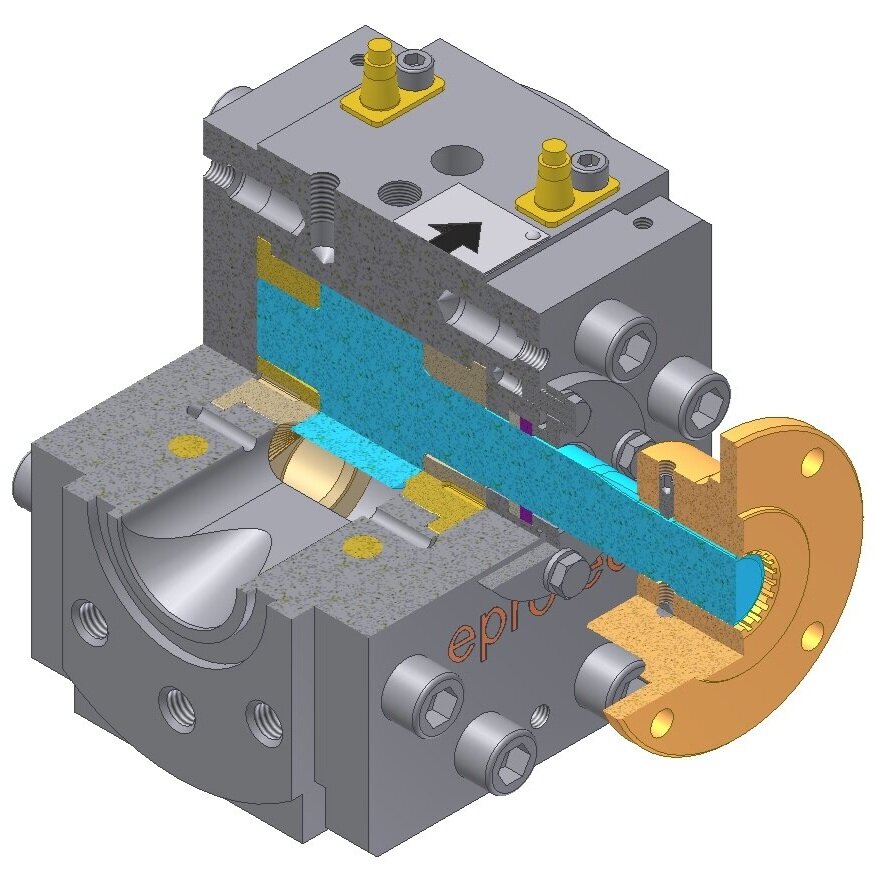

e p r o t e c melt-X MB

MELT-BLOWING is a unique process in which the molten polymer is blown by hot compressed air (250-300°C) to super fine fibres. A rotary drum (chill roll) or a belt with vacuum cools the hot filament to a diameter of 1 to 10 µm and produce a non-woven web.

The eprotec melt pump for melt blown (spun fleece) was especially developed 2020 in due time for mask filter production to process extremely low-viscosity PP (MFI 1500).

We produce the melt-X MB in large series.

melt-X MB for high MFI polymers