In addition to the performance of the eprotec extrusion melt pump, personal contact and after-sales support are of enormous importance to us. Fast and competent advice and answers, prompt delivery of spare parts, even for most of competitors gear pumps, ensure high productivity of your extruder line.

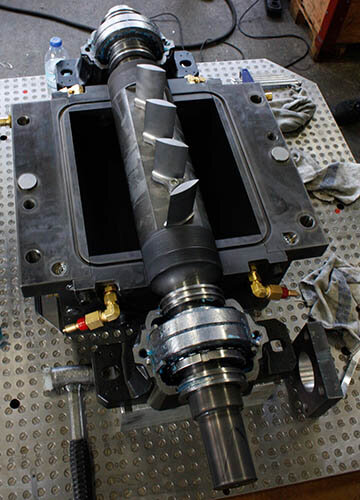

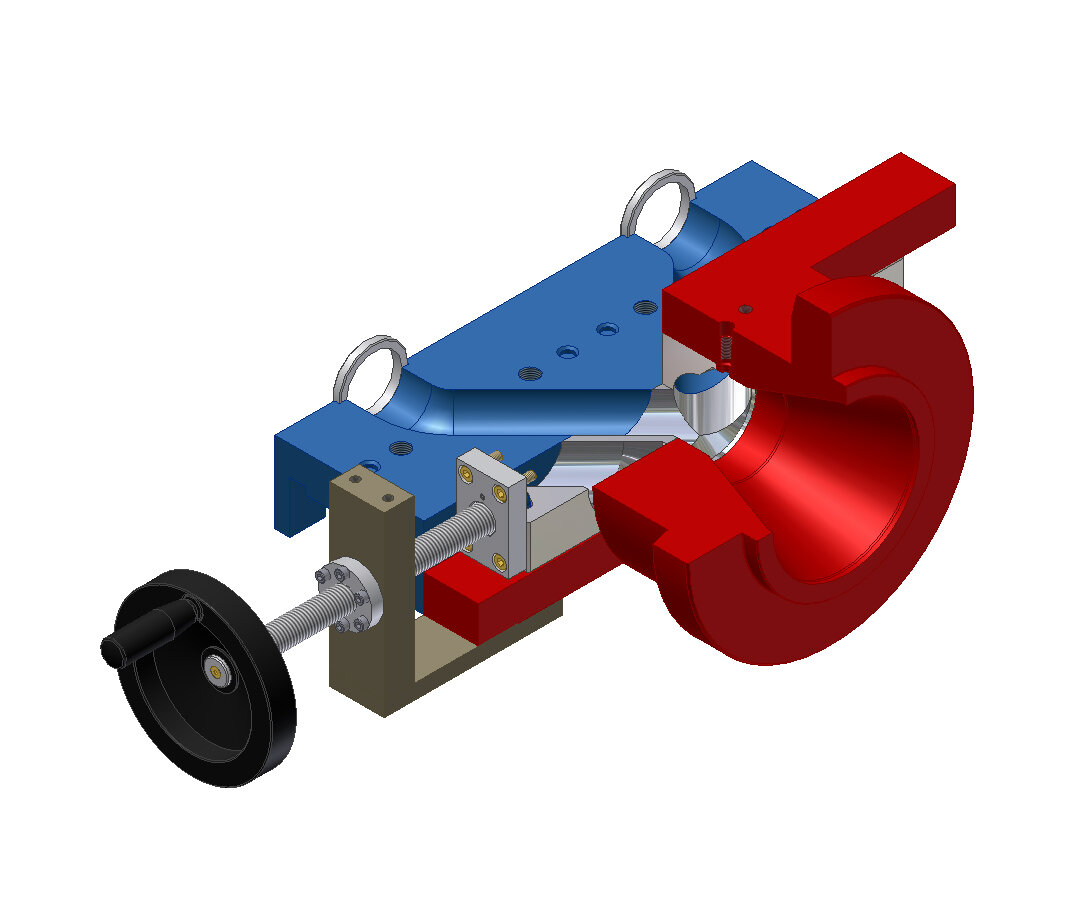

Rebuild, revision, overhaul

Maintenance work on the extrusion pump can be carried out by your staff. Our technicians can also support you on site.

We offer you to repair your gear pump in our factory. Our service team overhauls your gear pump from A to Z. Competent and reliable. From cleaning (vacuum pyrolysis) and condition assessment to assembly.

During the inspection of your melt pump - including competitor products - visual and significant dimensional deviations will be discussed with you. It is our goal to meet your requirements in the future pump application.

- That means more than just replacing components -

Your advantage is the high system availability and the avoidance of production downtime.

For you, this pays off in terms of productivity.

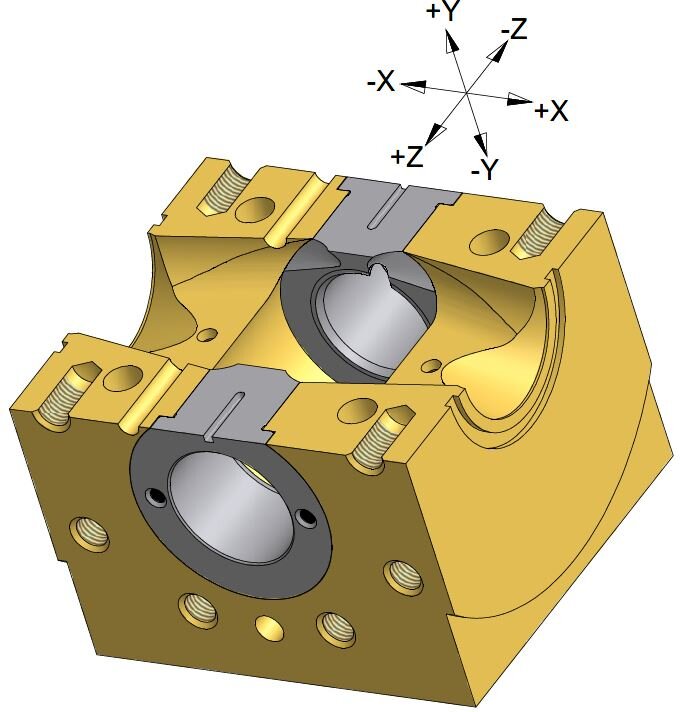

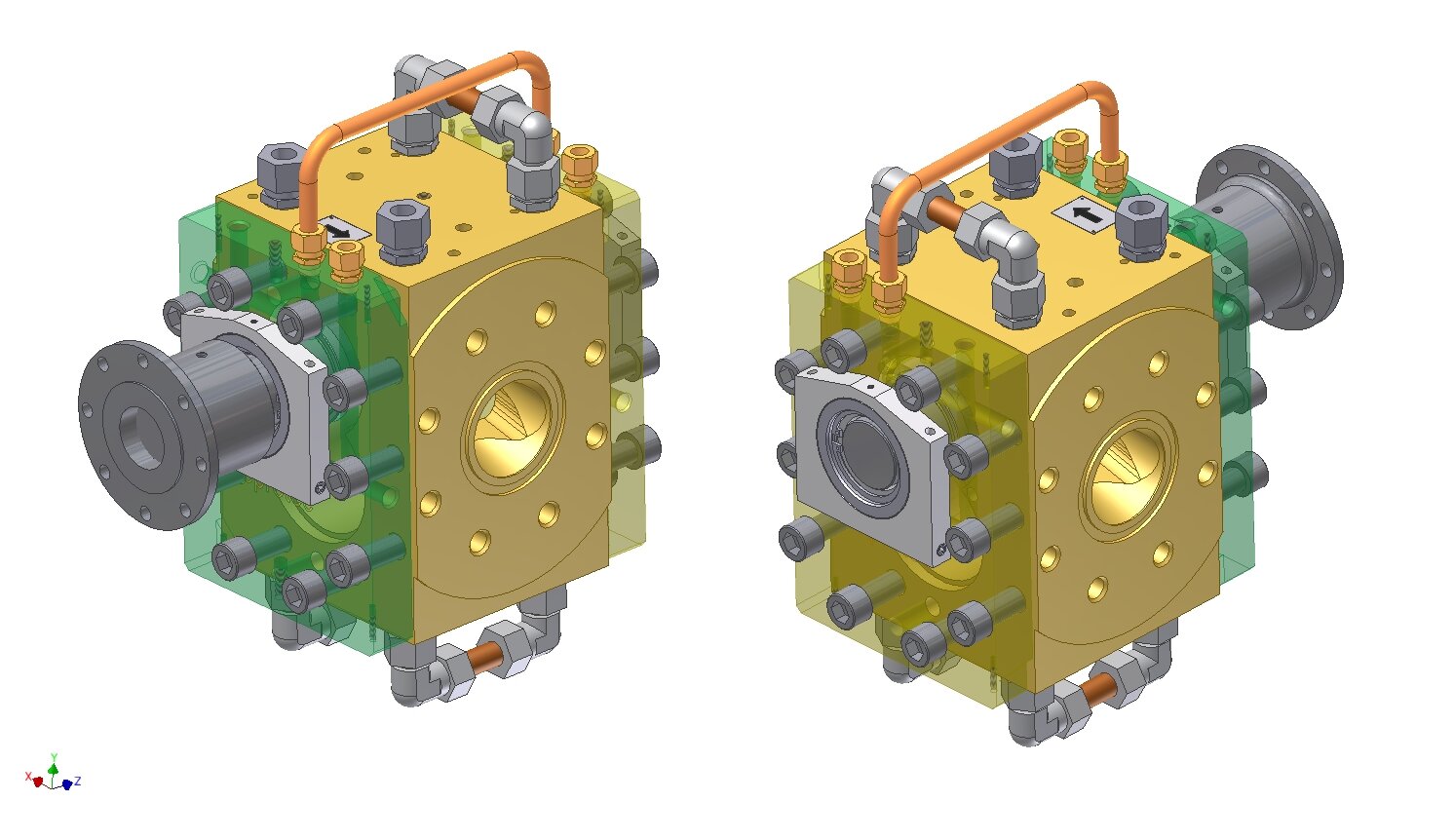

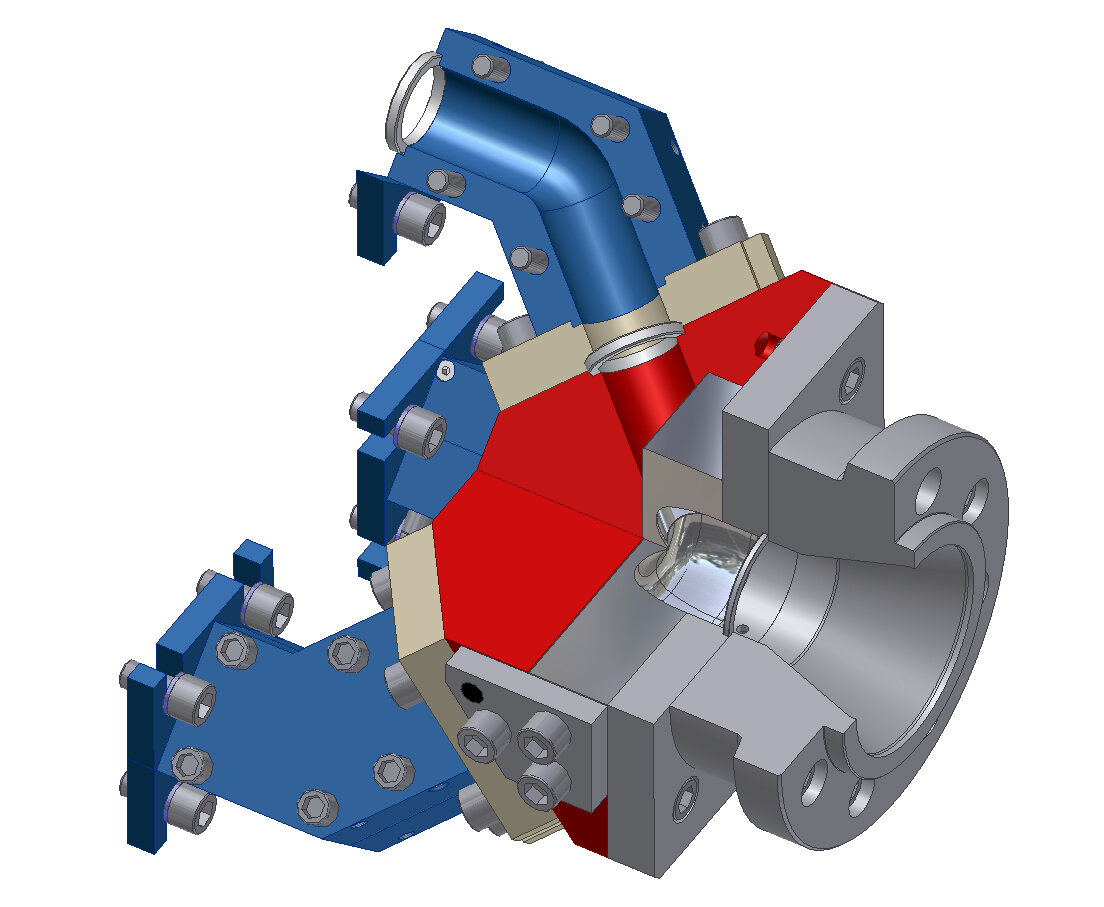

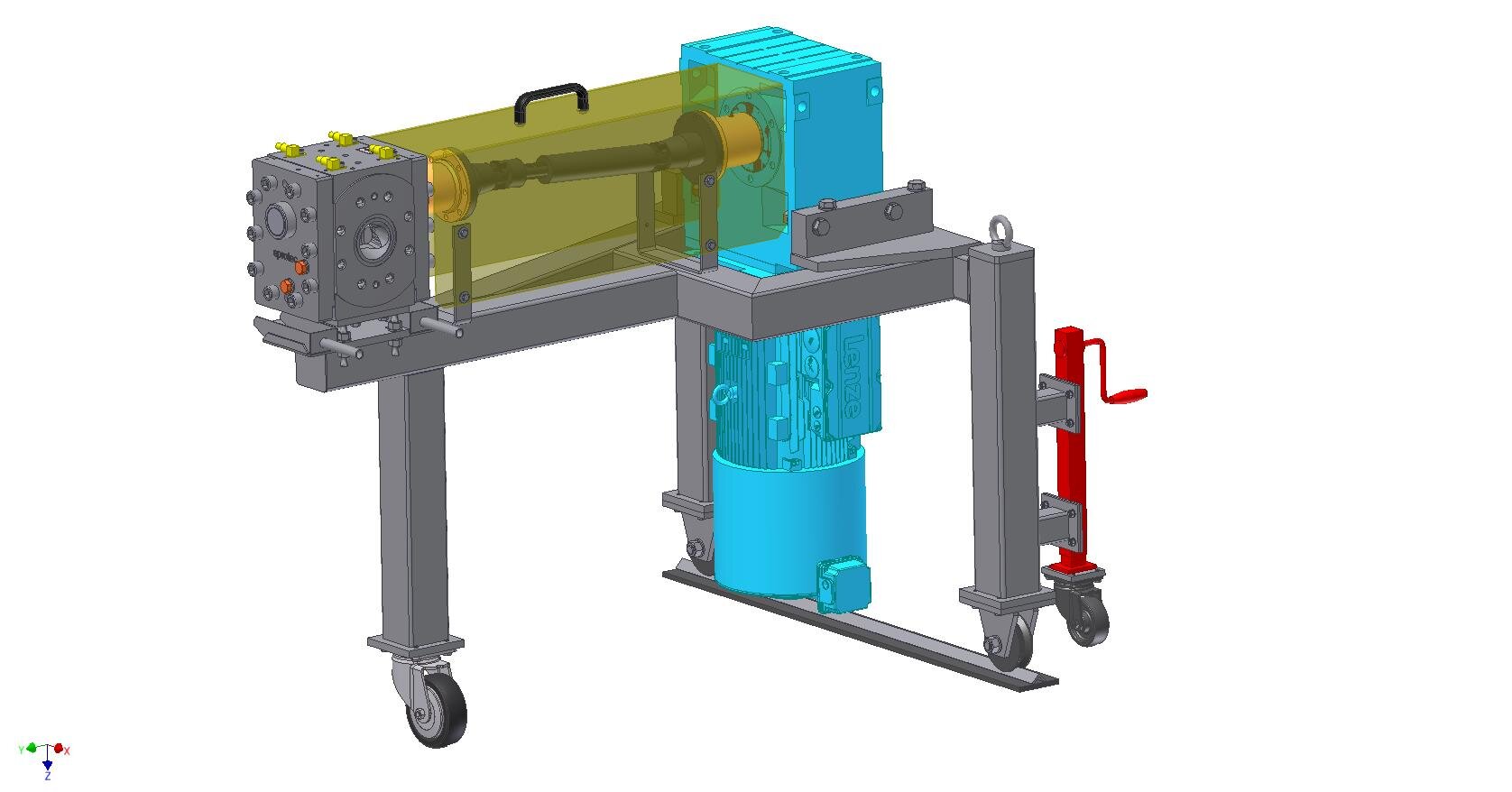

Engineering

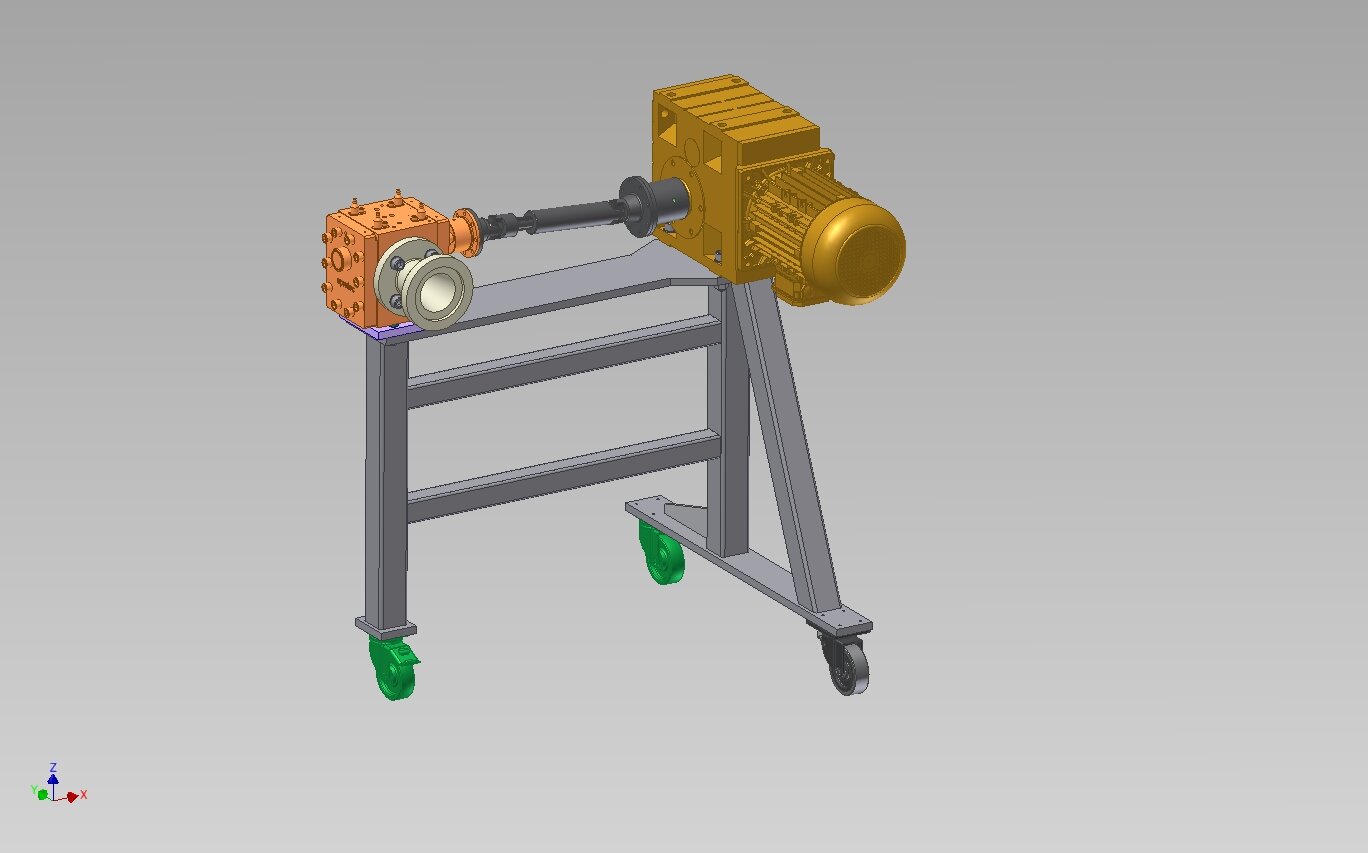

Engineering, the art of combining the important technical disciplines.

Thanks to our vast experience in melt pump assisted extrusion, know-how in mechanical engineering and CNC-manufacturing, we achieve tailor-made effective solutions.

In your high-tech process, every step must be mastered in order to reach your goal - beyond the commissioning phase.

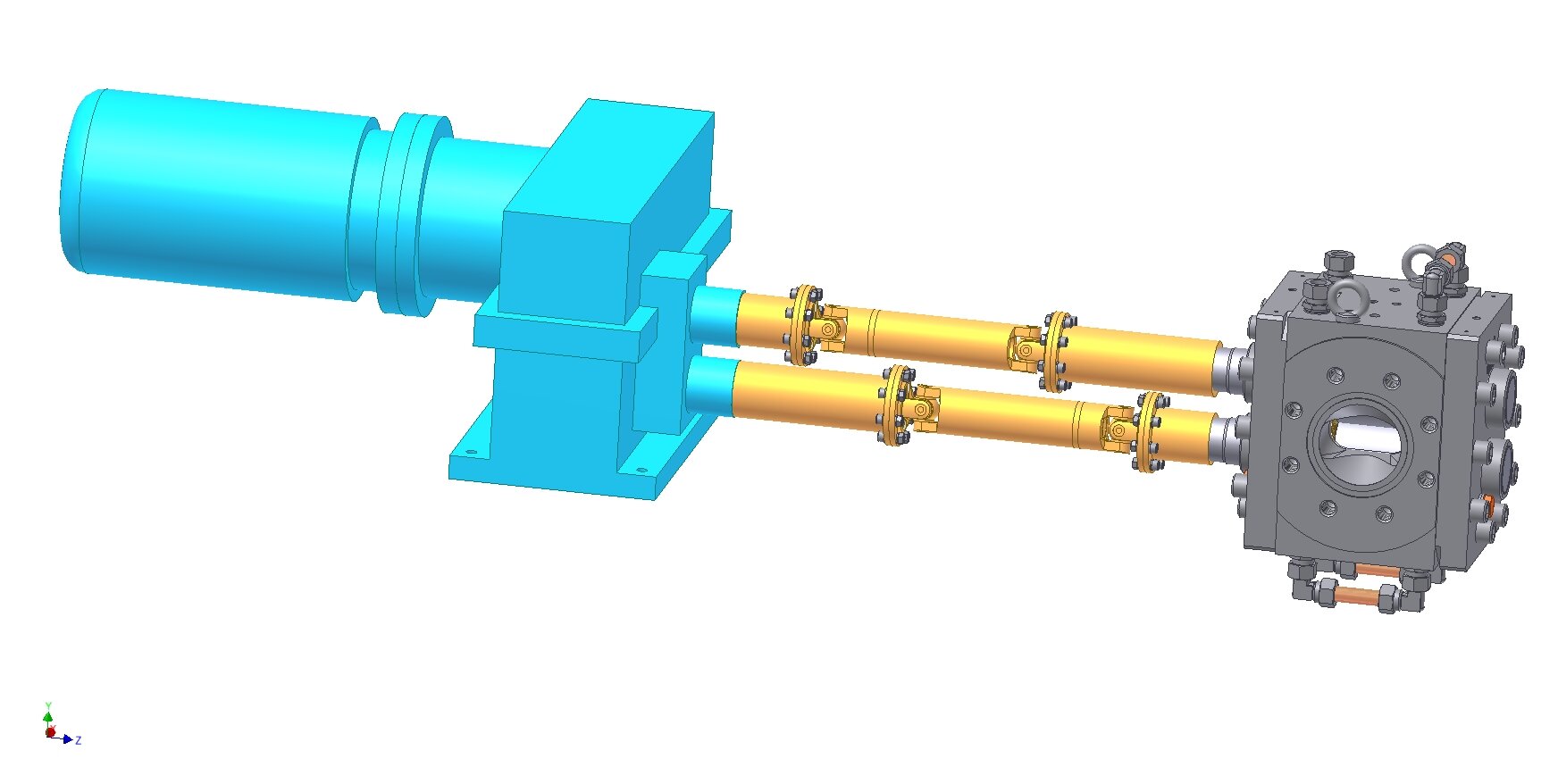

Extension of the service life

Different combinations of high-tech materials are implemented for the modular designed melt-X in order to fulfil the specific task. Special coatings, also for the complete pump, offer special protection against abrasion or corrosion. Slide bearings with good emergency-running properties and a long service life are not a contradiction in terms as eprotec impressively proves.